Front wheel wells

After a very long hiatus on the Citroën C6 deadening I am back. I haven't had that much time and the car is so silent as it is now, but I still have a lot of things I want to do in the C6. The rear doors and the roof for example, but before that it was time to attack the wheel wells.

On the 406 Coupé to reduce road noise I applied eXvibration on the wheel wells and the tyre roar was significantly reduced. The C6 is a different beast, there is less rolling noise from factory than on the 406 with deadening. Citroën used fabric wheel well covers to stop noise propagation from rocks projected by the tyres and added some extra deadening material at the back of the fabric covers.

So my idea was to remove the front covers and apply Dynamat Extreme to further reduce rolling noise, if it was even possible. I had discovered some old silver sheets of Dynamat that were left from the 406 deadening so I used them here. No point in adding Dynaliner since the covers are made of fabric and already do the same job.

I know what you are thinking, I should apply Dynamat from the interior of the car, as I did when deadening the boot, but this would mean I would need to take the dashboard out and the carpet.

So I took the covers out and was amazed. Each cover weigh more than 1Kg, but that alone doesn't explain why the C6 has such low rolling noise inside the car. After further inspection I saw that a deadening material that reminds me of Brax eXvibration was applied inside the wheel well. Knocking on the metal gave no rattles at all, very solid indeed.

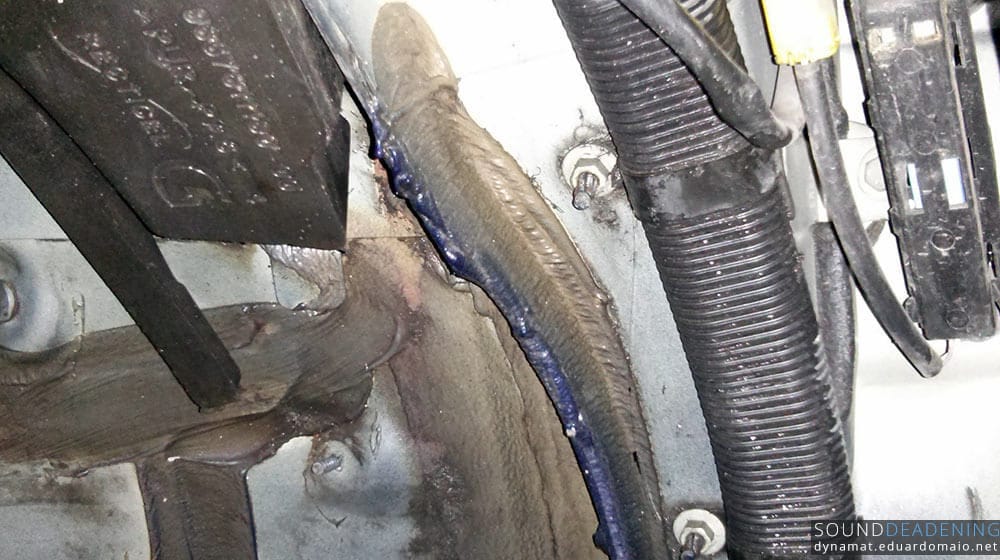

Also, and this is a testament to the build quality of the car and the attention to detail to make it as quiet as possible, where the metal panels are sandwiched together a rubberized panel sealing was applied. This effectively decouples different metal panels of the car, reducing vibration and noise propagation.

By the way, learn from my mistake. I had just washed the car, so I didn't think this would be an issue. When taking the cover off a lot of dust was coming off it, some brake dust was there and this is terrible for the respiratory system. I removed the second cover with a mask to avoid breathing that dust and would advise others to do the same if they are to tackle this kind of job.

Also, my apologies, pictures were taken with my mobile phone and not with the camera and tripod, so some are not that sharp and the colour quality is not the best.

On top of the wheel well was also a very thick piece of foam covering an opening that would probably propagate noise to the interior.

I started on the passenger side, and after a good cleaning it was time to plan where I would add Dynamat. The factory deadening was a good help, as this would indicate the problematic spots were noise would propagate.

But things didn't go according to plan. That eXvibration like material is very uneven and porous. Great to absorb noise, but Dynamat would not glue into it, no matter how much pressure was applied. It was time for plan B, so I added Dynamat Extreme on the most outer side of the wheel well and the top part were the bare metal is exposed.

This is the result.

As usual, with the cover back in place, after a proper wash of course, no Dynamat is visible.

So, with the passenger side done it was time to do the side on the drivers side. Unfortunately I didn't have as much space, some cables were routed in the outer most area of the wheel well and some screws were protruding.

So I applied Dynamat were it was possible and this is the result.

Notes and the result

I used less than half a sheet of Dynamat since I was not able to add Dynamat to the entire wheel well. So only about 400g extra weight, probably almost as much as I have removed in dirt from the covers, so win-win. Just kidding of course, but it was a lot of dirt.

It was not hard to do at all, thanks to the Hydractive suspension on the C6 I put the car in the highest setting, removed 2 plastic clips, 3 screws and the entire cover was off in a matter of minutes. Access is not hard and the panels are pretty much straight, so it was a breeze.

Now, the results. At lower speeds there is no difference, the Michelin tyres help. At higher speeds there is a difference, the rolling noise now enters the car prominently by the floor. I'm pretty sure what made this possible was the Dynamat in the outer area of the wheel well. But the difference is minimal, I even tough it was probably a placebo effect but went to a cobblestone road and I could pinpoint where the noise was entering the car.

Regarding the dB measurements, no differences.

So, was it worth it? To me yes, but if you have a C6 and want to completely remove rolling noise the best option is to add Dynamat to the floor and firewall. This is something I don't know if I'm going to do, but we'll see.

Done in 3 of June, 2017