Roof deadened and C pillars revisited

Tackling the roof deadening was quite a job. After removing the headlining there is little space to work because the headlining is still inside the car, sitting on top of the seats. Good thing that the roof is just a straight and long panel which makes it easier to work.

C pillars

Since the C pillar trim had to be partially removed I added polyethylene foam to fill it and added some Dynamat Extreme on the area that was covered by the headliner.

The roof

My main idea with the roof was to lower the cabin temperature, and as a bonus stop listening to the rain hitting the roof and stop some air borne noises.

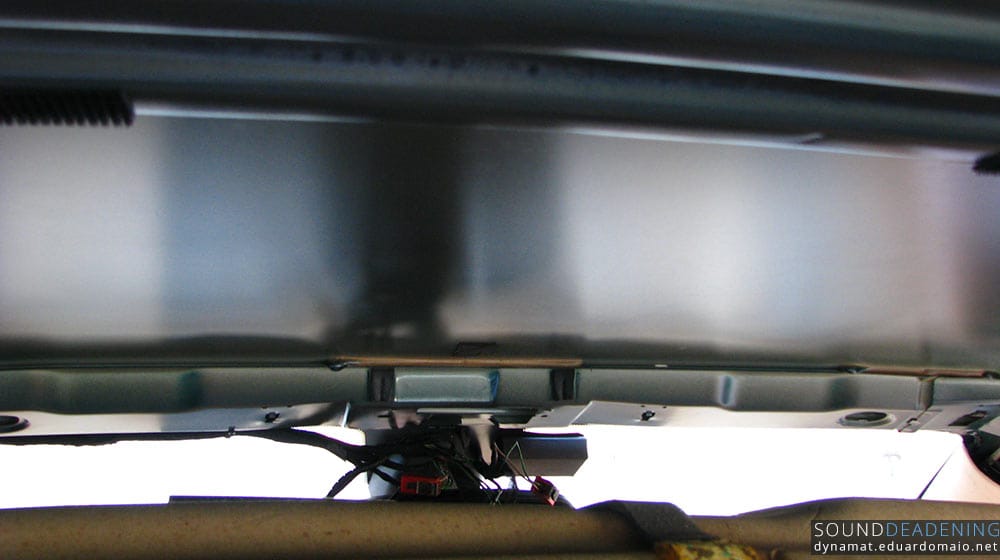

Apart from the central roof reinforcement the rest is just a straight panel, that will be a joy to apply Dynamat on. Also there is any sound deadening material there from factory, just some foam to decouple the headliner from the roof and form some sort of air box to reduce the temperature on the roof.

I started at the back, applying first polyethylene foam on the hollow areas. Since no cables pass thru there I could fill it fully without any issue. After this Dynamat Extreme was applied and the difference was immediate. I usually knock on the metal to see the sound it makes, and now there is no resonance.

After this a Dynaliner 1/8" was added. My idea was to add Dynaliner only at the front of the roof and glue some polyethylene foam at the back, but with time probably the foam would come lose and I'm sure it would not block heat as effectively as Dynaliner.

Since I would not apply any Dynamat on the hollow rear part of the roof I added fabric looming tape to avoid the foam falling in the future. It's nicely packed in there, but better safe than sorry.

Just like on the back of the roof, on the front area Dynamat and Dynaliner was applied. The central roof reinforcement didn't get any Dynaliner because there was no space there.

On the sides of the roof Dynamat Extreme was also applied as you can see on the picture above.

After putting everything back in place I had an issue with the headliner. I think the direct sunlight deteriorated the fabric glue and some parts started sagging. It's not much, barely noticeable, but I don't like it. I tried to use hot water to see if the fabric would shrink. It solved the issue in some smaller areas, others not so much. I guess a replacement headliner is in order then.

Anyway, the good part is the difference in the noise. Driving in the highway the wind noise is much lower. I then parked near the airport and could only listen to the noise of the jet engines thru the windows, it's an amazing feeling.

It's not church quiet and it will never be I'm sure, but it feels like some luxury cars.

Done in 5 of July, 2010